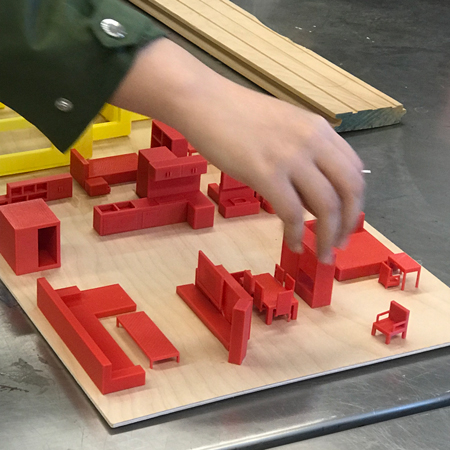

The UVM FabLab offers the use of its 3D printers to help students rapidly prototype small parts that would otherwise be difficult to manufacture or acquire. Keep in mind that FabLab resources can only be used for school-related projects and that, like any manufacturing process, 3D printing has physical and cost limitations that differ by machine.

3D Printing Guidelines:

The following guidelines will help you determine whether your design is suitable to print in the FabLab:

- Your part must not be too small:

- If features are smaller than the printer’s resolution, they will not print reliably. This is typically any feature smaller than 0.4mm (.016 inches)

- Your part must not be too big:

- It should not use too much material or print time.

- It must fit within the dimensions of the printer.

- Your part must be structurally suitable for printing:

- The part must not be too delicate or have large unsupported sections.

- Your pust must comply to our printing policy.

- We do not print weapons, weapon parts, drug paraphernalia, or copyright designs.

If your part is rejected for any of the reasons above, you are always welcome to modify the part and resubmit it for review. Our Fabbers are experienced and able to provide feedback on your designs throughout the design process.

Equipment (Quantity):

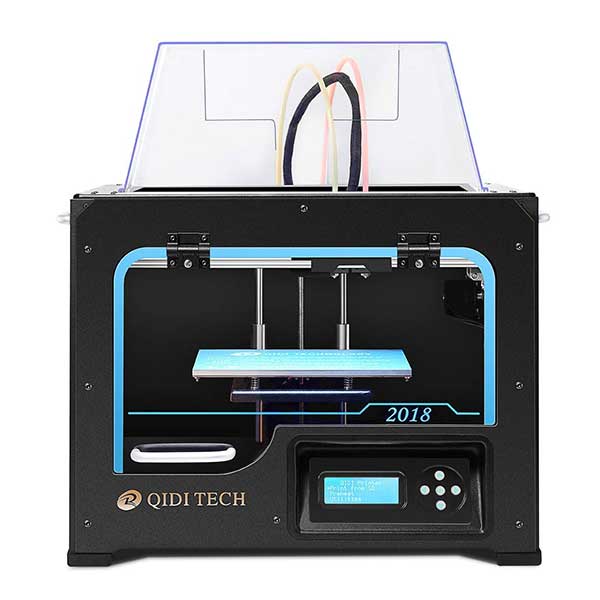

Extrusion-based 3D Printers:

Stereolithographic 3D Printers:

Elegoo Saturn 4 Ultra

Printer Specifications:

| Machine | Build Volume Dimensions | Material Types |

| Makerbot Sketches | 5.9″ x 5.9″ x 5.9″ | PLA |

| Stratasys F170 | 10″ x 10″ x 10″ | ABS/QSR |

| Qidi Tech I | 9.05″ x 5.9″ x 5.9″ | PLA |

| Bambu X1 Carbon | 10.07″ x 10.07″ x 10.07″ | PLA, Support for PLA, PLA-CF |

| Bambu P1P | 10.07″ x 10.07″ x 10.07″ | PLA, Support for PLA, TPU |

| Prusa Mini | 7″ x 7″ x 7″ | PLA |

| Prusa XL | 14.17″ x 14.17″ x 14.17″ | PLA |

| Elagoo Saturn 4 Ultra | 8.5″ x 4.8″ x 8.6″ | Resin |

About Extrusion-based 3D Printing:

3D printing is a type of ‘additive’ manufacturing, which is the opposite of the traditional way of fabricating objects where material is removed to produce the desired product; like creating a clay sculpture. These machines heat thermoplastic filament (i.e. PLA and ABS) and extrude layer by layer to form the desired product. A 3D file is formatted within printing software to create a toolpath for the extruder that will create the shell of the product as well as an infill pattern within the shell to improve strength.

Some extrusion-based 3D printers can print model filament with a chemically soluble or breakaway support material simultaneously, which improves the resolution of the finished product and allows the fabrication of complex geometries and hollow shapes.

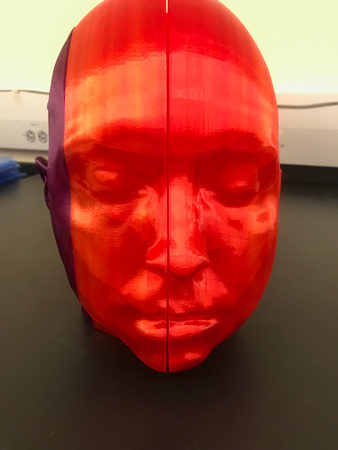

About Stereolithography 3D Printing:

An alternative to extrusion-based printing, stereolithography is a type of ‘additive’ manufacturing that involves photopolymerization of resin in a bath via a laser that cures the resin into hardened plastic layer by layer. This process forms solid products with isotropic properties. Our photopolymer resin materials include grey, clear, and white colors, as well as wax resin for casting parts.

Please keep in mind that 3D printed parts are not free! The FabLab sponsors each project for coursework, senior design, and some clubs and we only use approved materials for the safety of our Fabbers. For Engineering senior design budgets, prints are billed on a per-ticket basis, with the exception of the FormLab resin printer, in which case the SEED team should plan to purchase their own cartridge and tank. Beyond a single print, undergraduate students, graduate students, and faculty must pay the College of Engineering and Mathematical Sciences for the material used via a UVM chartstring.

Professional manufacturing options are available on and off campus. If you have a print job that is too large or time-consuming for the FabLab’s capabilities – for example, if you need a large number of parts made – this may be a better option. These facilities include the UVM Howe Library, Instrumentation and Modeling Facility (IMF) Labs, Shapeways, and the Generator Makerspace in downtown Burlington. If there is a well-founded reason this part must be 3D printed in the FabLab, such as extreme time constraints or lack of other options, please contact us at fablab@uvm.edu.