In the Spring of 2024, the Fablab, along with the SEED program, purchased three new Bambu X1 Carbon 3D printers with Automatic Material Systems (AMS’s). These machines have already proven to be a tremendous asset for the lab since they provide high quality 3D prints in a fraction of the time it would take some of our other machines.

These systems also provide increased flexibility for the lab since they are able to use four different materials on the same print. This can be used for multicolor printing, or for storing multiple support materials. These machines are currently configured to store two different colors of PLA (Polylactic Acid), a breakaway support material, and PVA (Polyvinyl Alcohol, a water soluable support material). This allows us to choose the best type of support for the project we are working on and ensure the highest quality part.

We are also able to print in advanced materials that create stronger parts. One of these materials that we have experimented with is PLA with Carbon Fiber. The addition of carbon fiber into the PLA greatly improves the strength of the material. The Bambu’s come with a Hardened Steel Nozzle and an Engineering Build Plate which makes printing with this type of material possible.

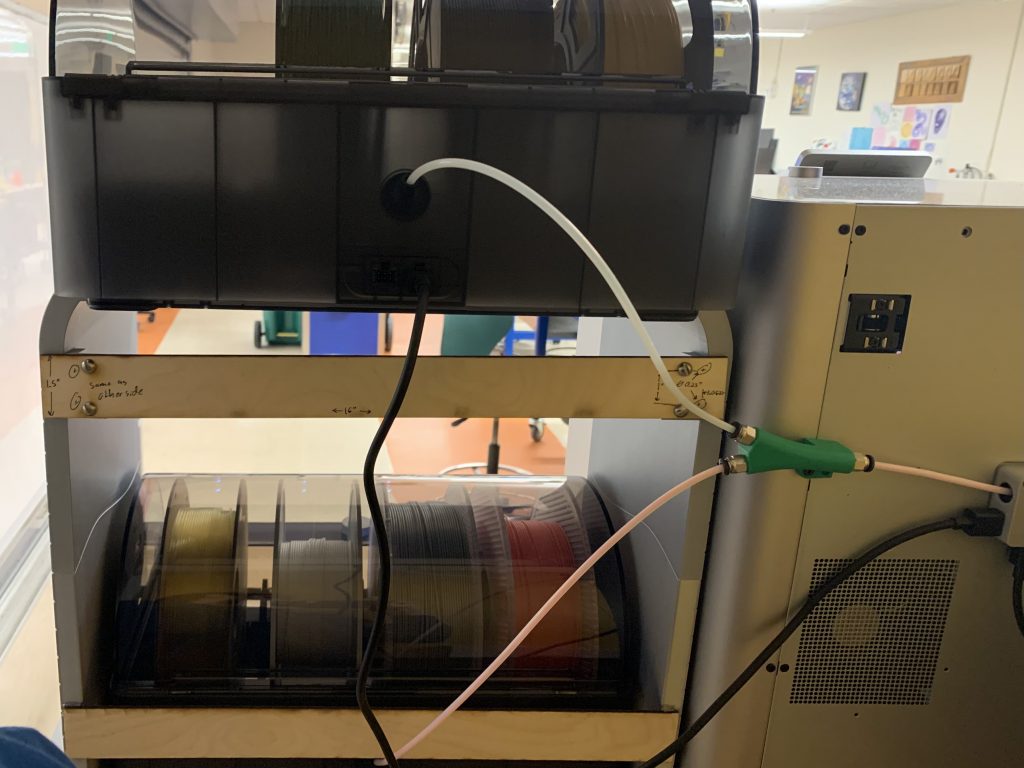

One exciting project that we have been working on with the new Bambu X1 Carbons is the addition of another AMS unit which would allow one printer to use up to eight different materials. This would allow use to store two different types of support material, Carbon Fiber PLA, and five different colors of PLA. This could help accomodate multi-color printing, possibly allow us to take requests for specifically colored prints, or provide for flexibility for other materials in the future. The two AMS units are stored next to one of the printers on a stand designed by “eclermontet” that was found on thangs.com. The two tubes that carry filament to the machine are merged together by a Y-Splitter designed by “Hans-G” found on Thingiverse. To improve the structure of the stand, a custom bracket and support brace were designed and created using the Bambu’s and the Epilog Laser Engraver. The pieces stopped the stand from swaying while the printers were printing.

We’re very excited to be able to use these machines and look forward to being able to explore all of their possibilities going forward!