The UVM FabLab provides digital fabrication services for the University of Vermont community. In this new video, you’ll hear from the UVM Students who run the lab’s day-to-day operations. Our team looks forward to working with you!

*NEW* Bambu X1 Carbons

In the Spring of 2024, the Fablab, along with the SEED program, purchased three new Bambu X1 Carbon 3D printers with Automatic Material Systems (AMS’s). These machines have already proven to be a tremendous asset for the lab since they provide high quality 3D prints in a fraction of the time it would take some…

Eclipse Hours

The FabLab will be closed on 4/8 so that everyone can enjoy the solar eclipse! Hours will remain normal for the remainder of the week.

Welcome to 2024!

HAPPY NEW YEAR!!! We’re back from winter break and we look forward to working with you this semester. Our new hours will be posted soon. In the meantime, feel free to email or message us over teams at fablab@uvm.edu. We will have open hours the first week of classes.

Happy Holidays!

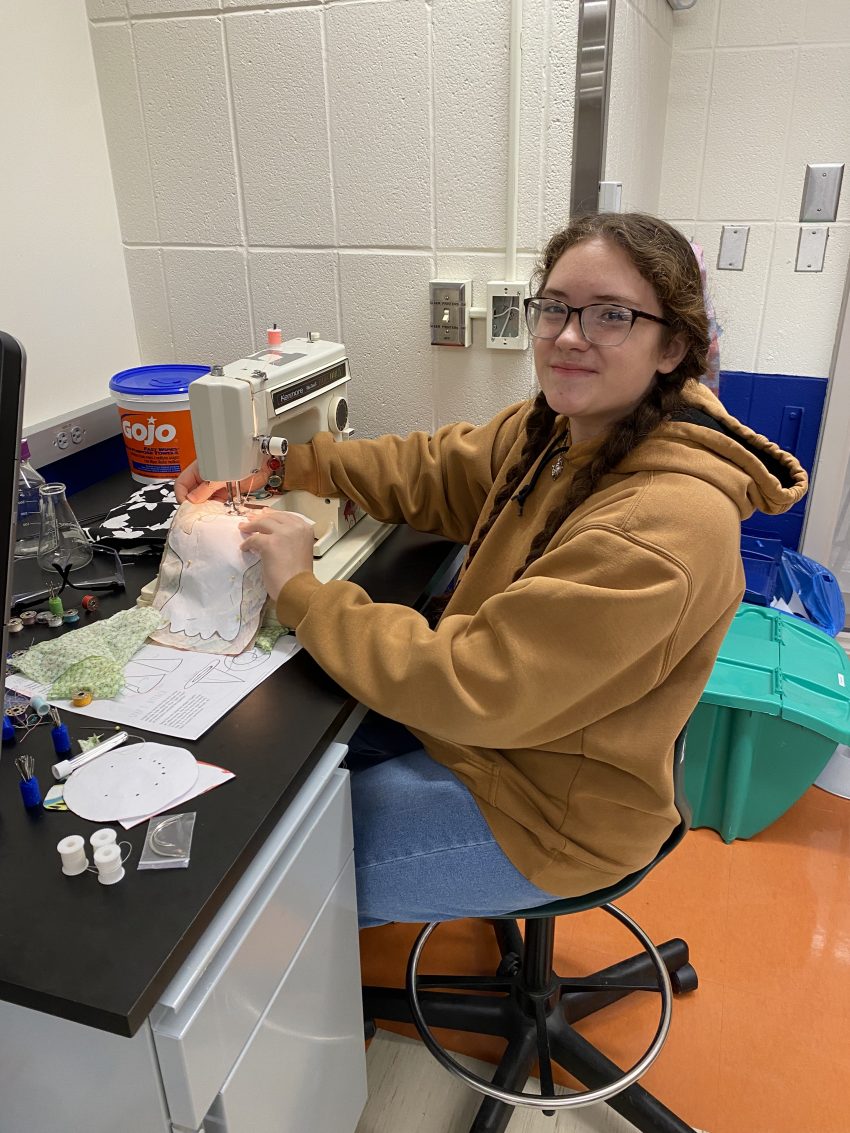

We love it when students use our sewing machine to mend and remix clothing. Many UVM students are concerned with the environmental impact of fast fashion and they proactively seek ways to counter its negative impacts through repairing clothing, buying used clothing, and remixing worn clothing.

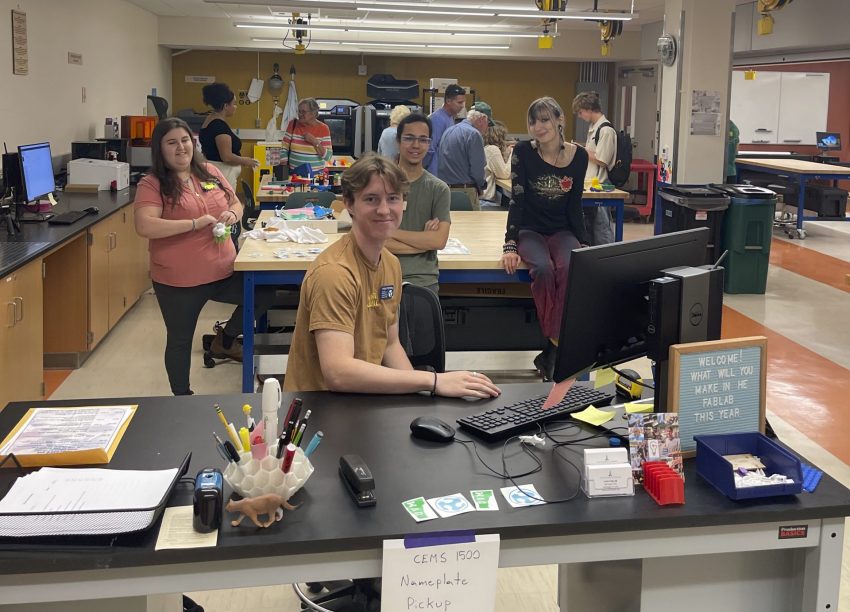

UVM WEEKEND 2023

FabLab Open House! Fabrication Laboratory Open House and Demonstration Saturday, September 30, 11:00 a.m. to 1:00 p.m. | Votey Hall, 2nd Floor Discover creation and design through use of the UVM Fabrication Lab’s cutting-edge technology. An open house and demonstration for UVM weekend of the laser cutting and 3D printing resources available to UVM students,…

Fall 2023 Workshops

It’s official! The fall 2023 semester is in full swing and you know what that means: a fresh set of workshops courtesy of the UVM FabLab. Attached to this post is our workshop schedule for this semester — they’re open to anybody who wants to learn more about the lab, or who simply wants to…

Art + A.I. Education in the UVM FabLab

This week we hosted numerous Art + AI outreach programs in the University of Vermont FabLab. We worked with UVM Extension and Vermont 4H and the UVM Upward Bound Program. Thanks to @karsonr06 for assisting! We’re grateful for funding from the National Science Foundation under award 2218063 and support from Nick Cheney’s research group and…

See you in September!

The FabLab is on summer break and will resume regular services in September when our team returns to campus. In the meantime, if you need digital fabrication services we highly recommend UVM’s IMFLabs. If you are looking for a hands-on experience with fabrication tools consider a membership at the Generator Maker Space. Every year, Generator offers…

Exam Week Spring 2023

Another semester, another exam week, and we all know what that means: go go go! To help ease your burden the FabLab will be open at the following times to assist you in meeting those last minute deadlines: Monday: 9:00am – 12:00pm & 4:00pm – 7:00pmTuesday: 11:00am – 3:00pm & 5:00pm – 9:00pmWednesday: 8:00am –…