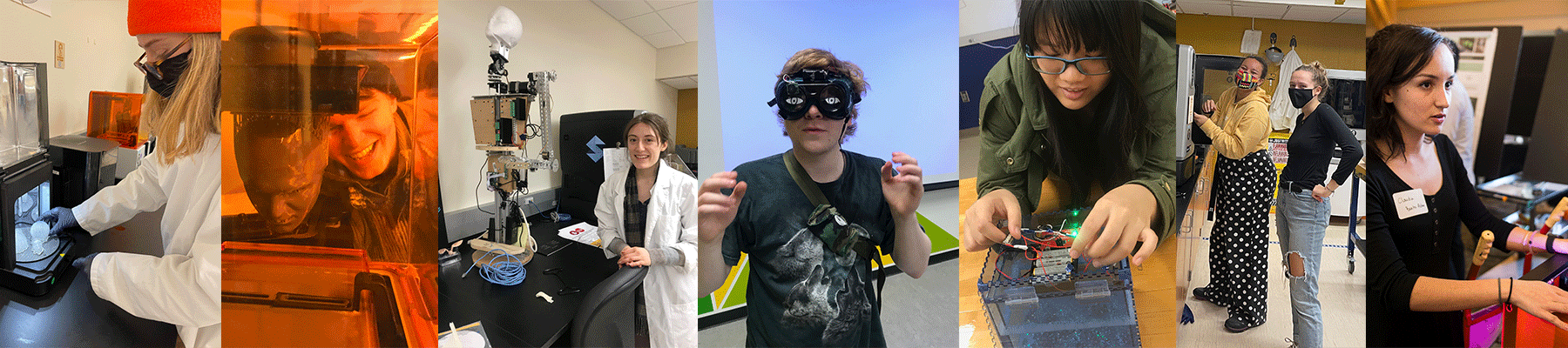

The UVM FabLab provides digital fabrication services for the University of Vermont community. In this new video, you’ll hear from the UVM Students who run the lab’s day-to-day operations. Our team looks forward to working with you!

Category: 3D Printing

*NEW* Bambu X1 Carbons

In the Spring of 2024, the Fablab, along with the SEED program, purchased three new Bambu X1 Carbon 3D printers with Automatic Material Systems (AMS’s). These machines have already proven to be a tremendous asset for the lab since they provide high quality 3D prints in a fraction of the time it would take some…

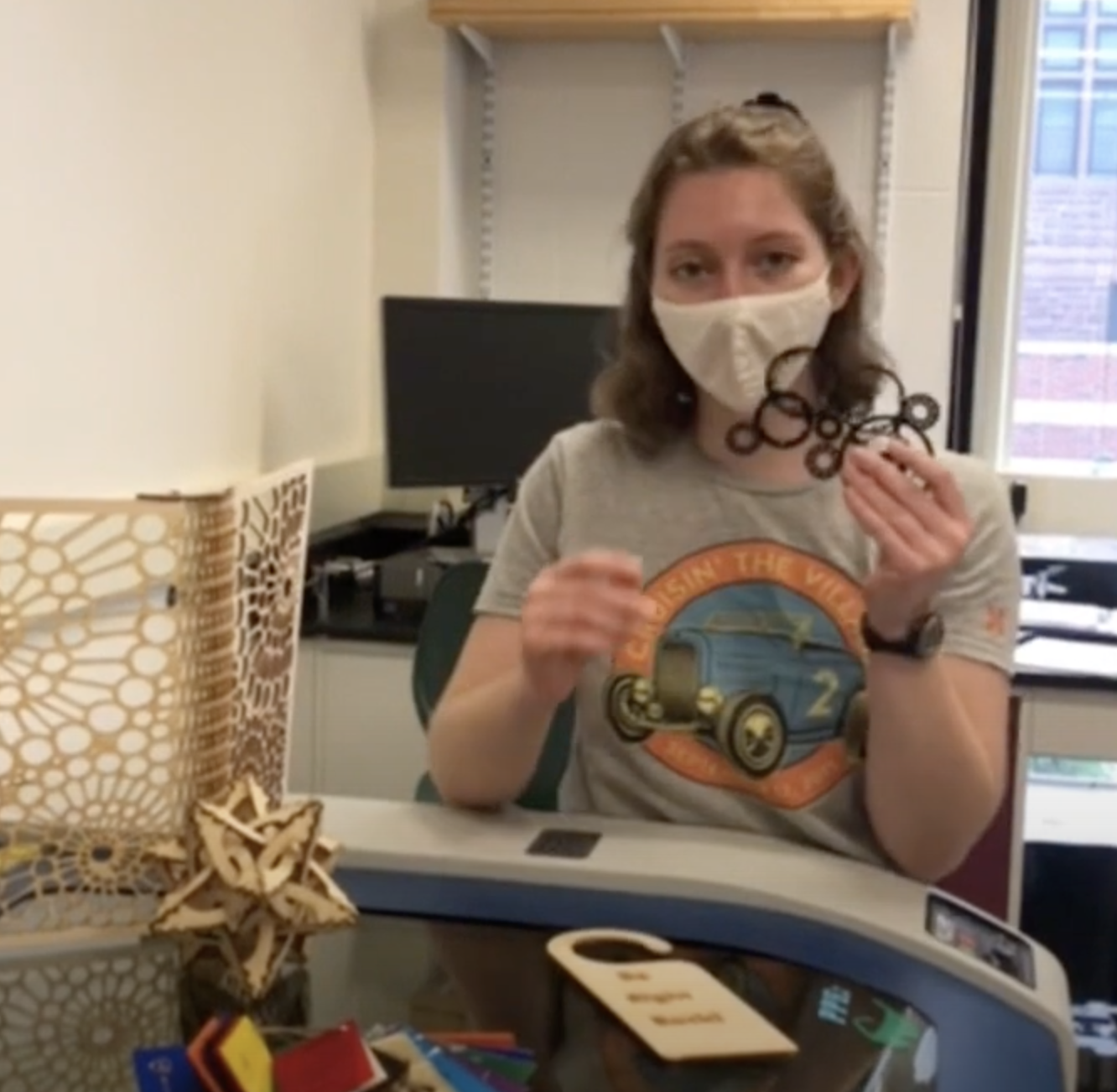

Welcome to the UVM FabLab!

A virtual tour with student employees (and Fabbers) Shannon and Olivia.

UVM FabLab staffer Matt Argraves uses 3D printing to enable tractor safety

By Sarah Tuff Dunn Nearly as much as maple syrup and ski slopes, tractors are a motif of Vermont—but driving one safely is more complicated than some might think. So UVM had a unique opportunity lately when Liz Kenton at the Center for Sustainable Agriculture reached out to the school’s FabLab for help ensuring safety…

Maker Metrics: Measuring the Impact of Academic Makerspaces

By Jenn Karson We know that academic makerspaces create meaningful experiences for students, yet how do we measure this meaningful impact? Where do we start? Last fall on behalf of the UVM FabLab I attended the first International Symposium on Academic Makerspaces (ISAM) at MIT. Organizers for the symposium came from MIT, Yale, Stanford, Olin, Carnegie Mellon, Case…

UVM FabLab Student and Faculty Projects Highlighted

The Spring 2017 issue of Summit magazine highlights prototyping and research in the UVM FabLab! FabLab project article

Bamboo Fashion in the FabLab: 3D Printed Molds Mimic Bamboo

Bamboo is an appealing material for many purposes and worldwide because it is reliable, inexpensive and grows rapidly in varied conditions. As a 2015 Barrett Scholar undergraduate Civil Engineering major Sara Dorr created unique molds using the FabLab’s 3d printers that mimic the internal patterns bamboo fiber. These molds provided opportunities to experiment with novel distributions of…

Making “Greenspeed” in the UVM FabLab

The Alternative Energy Racing Organization (AERO) uses the FabLab almost daily during the school year to prototype different parts on their alternative energy racing car, Greenspeed. The machine they use most is the laser cutter. The laser cutter allows them to create quick cardboard prototypes to ensure proper geometry and measurements for car parts that…

3D Printing the Rank-3 Shi Arrangement

A challenge in many parts of mathematics is that of visualizing structures that live in four dimensions and higher. Such visualizations are crucial for intuition as often important mathematical intricacies do not arise in lower dimensions. In this project, the CEMS UVM FabLab helped Professor Warrington make a 3D print of a four-dimensional hyperplane…